History: More than thirty years at the cutting edge....

History

Founded in 1974 by Bernard Groom, Qualiturn Products is today one of the leading suppliers of precision mill-turned components in the UK. We also have a small but expanding overseas customer base.

In 1990, Qualiturn was one of the first subcontractors to start lights-out machining, with no operator attendance during the night shift. The company has operated 24 hours a day, 7 days a week, 365 days a year ever since, with only daytime staffing.

Today the plant list includes 18 Star CNC sliding-head mill-turn centres and 4 Miyano twin-turret fixed-head lathes. All have opposed counter spindles and are capable of single-hit machining of highly complex parts. Washing and inspection machines complete the plant line-up at our Hertford factory.

Currently run by second-generation Managing Director, Nick Groom, Qualiturn is a firm believer that a business is only as good as the employees.

The company trains its people in-house, producing a workforce that has in-depth knowledge of the company's machines and working practices. Shop floor staff are responsible for setting and operating the machines as well as for quality control. This varied job specification results high morale and employees staying with the company for longer than the industry average.

Reliable, on-time supply of components within tolerance at competitive prices is the key to Qualiturn's success. It is underpinned by our approachability, depth of experience and the commitment of the directors to continue investing to keep the company moving forward.

Please check out our News pages (top left), you will see that qualiturn does not stand still, we aim for continual improvement in both quality and customer service.

HISTORY OF QUALITURN – 1974 TO 2019

- FEB 1973 – Decision to start Qualiturn. Heard of 10 machines for sale in Suffolk, ex MK Electrics. Six Petermann and 4 CVAs.

- Late 1973 – Premises found in Brewhouse Lane, Hertford, a former laundry boiler house!!

- FEB 1974 – First orders from English Numbering Machines. Invoiced and delivered in March 1974.

- 1976 - Oil crises – leading customer cancelled all orders in May. Saved by orders from Unicorn Darts for gripper shafts. Went on to produce many 1000’s. First overdraft needed (Bank had our house as collateral).

- 1977 - Moved factory to Hartham Lane on the day our son Nick was born at 7.20am!!No pressure!!

- 1982 - First Wirth & Gruffitt second operation machine purchased. Eventually had six.

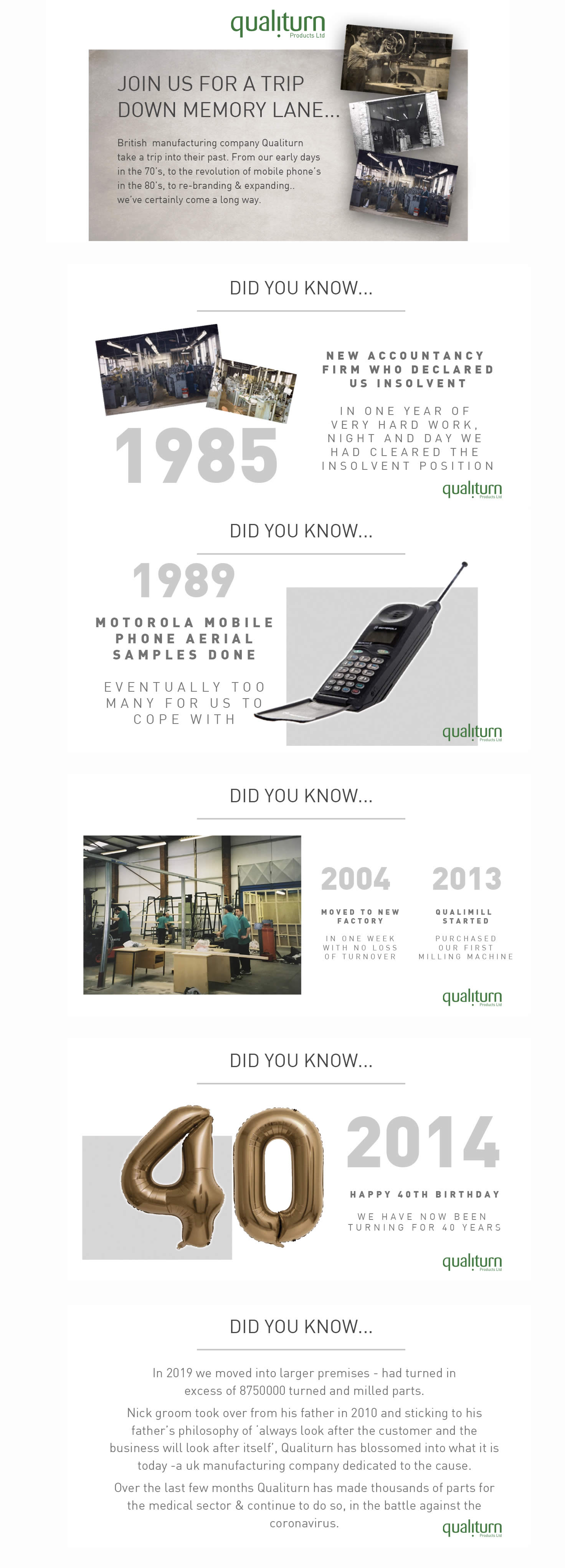

- 1985 - Accountant died while on holiday in Greece. Bank advised a new accountancy firm who declared us insolvent!! Overnight decision to give up or carry on (house on line!).

In one year of very hard work, night and day we had cleared the insolvent position and the bank were happy to back us again. - 1987 - Steve Aulton joined the Company.

- 1989 - Motorola mobile phone aerial samples done and orders commenced. Eventually too many for us to cope with.

- 1990 - first STAR machine bought and Steve ran it 24 hours a day, 7 days a week (night unmanned)

- 1991 - April budget insisted there was a recession but Motorola kept us afloat. Bought two more STARS against accountant’s advice.

- OVER next few years our investment in CNC STAR machines increased and we did night time unmanned running. We extended the factory front and back and then took two units opposite.

- 2000 - Nicholas Groom joined the company following an apprenticeship with Avdel Textron when they moved to the North of England.

- 2003 - Decision made to move as not efficient in three units.

- 2004 - Jan took keys for new factory and moved 1 ½ miles from west to east Hertford.

- 16 FEB - moved in in one week with no loss of turnover!!

- 2008 - expanded in to the unit next door unit 19

- 2010 - Nicholas groom became MD

- 2013 - Qualimill started, purchasing our first milling machine

- 2014 - Happy 40th birthday, we have now been turning for 40 years2014

- - Second Milling machine added to Qualimill

- 2015 - Qualiturn Purchase a New property

- 2016 - We increased our sliding head machines to 20. We now employ over 30 members of staff

- 2017 - Continued investment in machinery and staffing

- 2018 - 8750000 turned and millied parts manufactured

- 2019 - Factory move to Unit 7 Fountain drive.

- 2022 - We have invested considerable resourses in understanding our impact on the environment and have obtained our accreditation under IS0 14001, the internationally recognised environment management system.

- 2024 - An extension to the factory was built. The new extension is a purpose built GOODS IN area, allowing for better control of raw material stock.

Further Information

Get In Touch

Qualiturn Products Limited

7 Fountain Drive

Hertford

SG13 7UB

tel. +44 (0) 1992 584499

email. info@qualiturn.co.uk