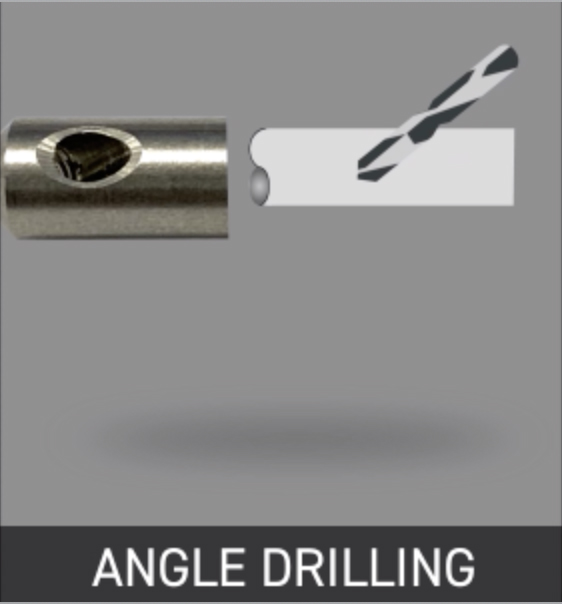

Angle Drilling

Specialisations: Angle Drilling

To drill holes at angle, the swing plate is clamped at required angular position with respect to cross slide. The drill bit is held in the chuck and drilling is done on the work piece by means of axial movement of longitudinal slide.

As we all know, Lathe machine is capable of doing almost all kind of operations, although, it is not able to do Angular drilling on work-piece. Further, it can't do indexing for drilling many holes on pitch circle diameter.

At first, the whole attachment is fixed on the lathe machine cross slide by means of bolting or clamps. The angle plates are two supporting structures which are used to support as well as allow rotary motion to the swing plate.

The angles are calibrated on the angle plate. Swing plate can be clamped at any angle with reference to machine cross slide by means of bolts. One hole is drilled in swing plate in order to support the mandrel on swing plate. One counter- bore with high accuracy and surface finish is made on the swing plate. In this counter-bored hole, one bearing is tightly fitted, for providing friction less rotary motion to the mandrel.

One groove is made in the swing plate, in which cir-clip will be fitted. The cir-clip will prevent the bearing to come out from the swing plate due to cutting forces. For doing quick indexing of job, one spur gear is fitted on the backside of the mandrel. The indexing pin and spring are used along with the spur gear to complete the operation.

Over and above, one slot will be made on one of the angle plate in order to permit the angular motion of the indexing pin along with the swing plate.

Request a quoteGet In Touch

Qualiturn Products Limited

7 Fountain Drive

Hertford

SG13 7UB

tel. +44 (0) 1992 584499

email. info@qualiturn.co.uk